by Victoria Fill | Apr 7, 2019 | DBF-Archive

Thomas Leitgeb, the vice team leader of Team Drone Tech, tells the story of how this project came to live: The idea of a tri-rotor tiltable Vertical Take-Off and Landing (VTOL) in flying wing configuration started out 1 year ago. The thought of being able to take-off...

by Victoria Fill | Mar 17, 2019 | DBF-Archive

Michael Lampesberger, a team member, was analysing the design process of an aircraft in his bachelor’s thesis. He performed his task by creating a historical flight model through reverse engineering. The foundation is the 1932 published blueprint of the so called...

by Victoria Fill | Mar 7, 2019 | DBF-Archive

Thank you for your support! On March 1st the teams’ official competition aircraft “BOBBY” was presented at the Roll Out Event. Numerous sponsors and other guests gathered in the aviation laboratory at the FH Joanneum in Graz, where the DBF-2019 team members awaited...

by Victoria Fill | Mar 3, 2019 | DBF-Archive

The need for drones is growing steadily. Therefore, new and more efficient concepts are needed especially for increasing payloads and as a replacement for helicopters. Benjamin Haller, a team member, wrote his bachelor’s thesis about such heavy-duty drones. A...

by Victoria Fill | Feb 17, 2019 | DBF-Archive

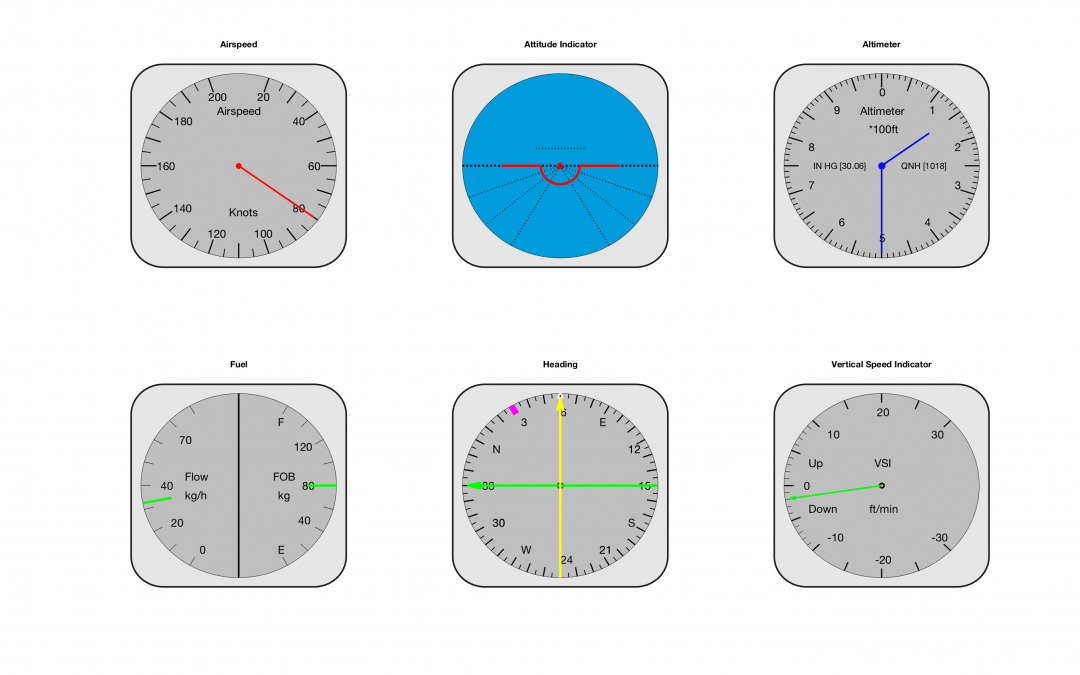

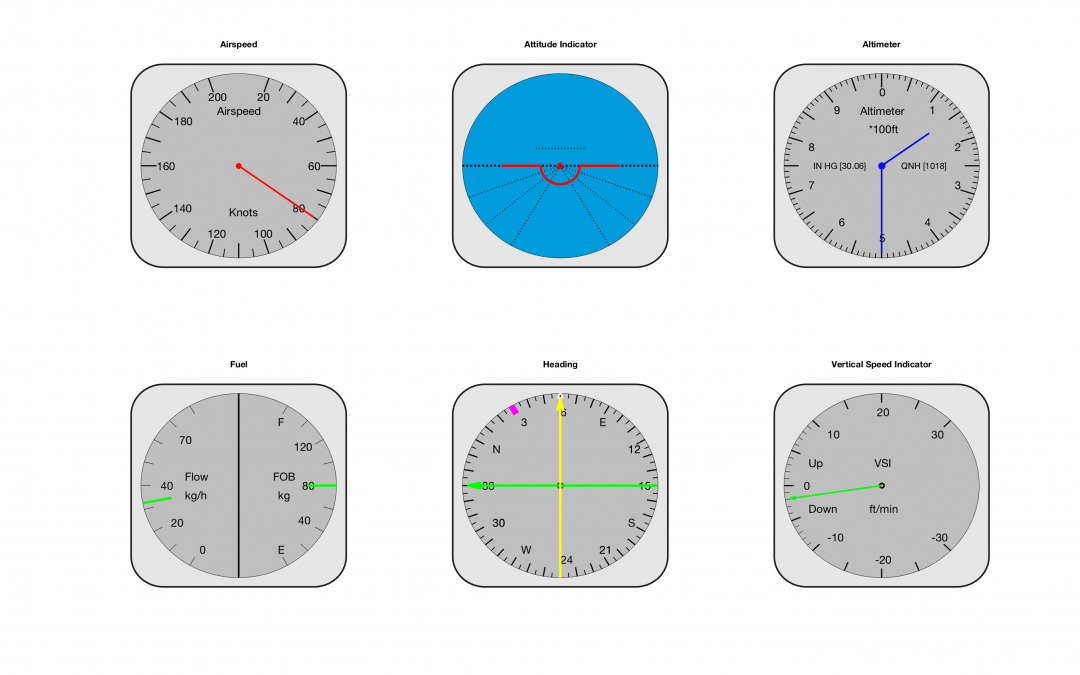

The aim of this project, which Arian Ghoddousi a member of Team Drone Tech is currently working on, was to compute and simulate aircraft flight data. The data output was designed to look like a common general aviation plane cockpit, like the Cessna C172. During the...